Ethylene oxide sterilization principle

Ethylene oxide gas has the characteristics of strong penetrability, broad spectrum of sterilization, thorough sterilization, no corrosion and damage to articles. By alkylation with the thiol (-SH), amino (-NH2), hydroxyl (-OH) and carboxyl (-COOH) on protein molecules and imino (-NH2) on nucleic acid molecules, proteins are forced to lose the reactive group, blocking normal biochemical reaction and metabolism. Accordingly, microbes die and the sterilization effect can be achieved.

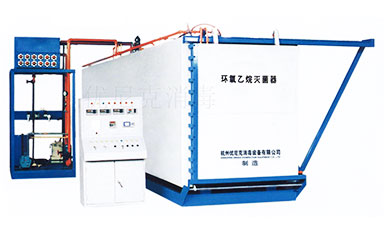

Full-automatic sterilizer

Criteria for implementation:

1. YY0503-2016《Ethylene oxide sterilizer》;

2. GB18279.1-2015/ISO 11135-2:2007《Health care products sterilization-ethylene oxide Part 1: Requirements for development, validation and routine control of sterilization processes for medical devices》;

3. GB18279.2-2015/ISO 11135-2:2008《Health care products sterilization-ethylene oxide Part 2: GB18279.1 application guide》;

4. ISO11135:2014 《Sterilization of health-care products ̶ Ethylene oxide ̶Requirements for the development, validation and routine control of a sterilization process for medical devices》;

Features of sterilizer configuration :

1. Using industrial computers SIEMENS and PLC to realize the automatic control of sterilization process and stable and reliable operation;

2. Using real-time monitoring devices to increase types of fault diagnosis, automatic alarm and automatic guard for secure operation;

3. The sterilizer monitoring and management system can provide multi-level account management for realizing that staffs have rights and operation record log individually;

4. Bilingual display of Chinese and English on computer interface and all the documents;

5. Display and print the data monitored and recorded in sterilization process in the form of reports and trend graphs, and the parameters are stored permanently;

6. Efficient heating system: using hexahedral hot water circulation heating; can be designed to be heated in whole waters, shortening the heating time, achieving the best temperature uniformity; enhancing the cooling system to quickly achieve lower temperature required;

7. Efficient pre-vacuum system: providing multiple vacuum system options; water ring type vacuum pump, oil-free rotary vane vacuum pump, leybold pump plus water ring vacuum pump.

Semi-automatic sterilizer

Features of sterilizer configuration:

1. Open and close the door in a translational style;

2. Gas-filled seal;

3. Stainless steel inner liner;

4. Automatic adjustment of main parameters;

5. Automatic record of sterilization parameters;

6. Automatic alarm and safety protection.

Primary technical parameters:

|

No. |

Model (m³) |

Outside size (L*W*H)mm |

Inside size (L*W*H)mm |

Number of loading trays (1200mm*1000mm) |

| 1 | HDX-1 | 1500X700X1000 | 1750X1100X1750 |

Customed pallet or loading trolley |

| 2 | HDX-2 | 1500X1000X1350 | 2000X1550X2050 |

Customed pallet or loading trolley |

| 3 | HDX-3 | 1850X1000X1670 | 2300X1550X2350 |

Customed pallet or loading trolley |

| 4 | HDX-6 | 2800X1350X1700 | 3250X1900X2400 |

Customed pallet or loading trolley |

| 5 | HDX-10 | 4500X1350X1700 | 4950X1900X2400 | 4 |

| 6 | HDX-15 | 6750X1350X1700 | 7200X1900X2400 | 6 |

| 7 | HDX-17 | 7400X1350X1750 | 7850X1900X2400 | 7 |

| 8 | HDX-20 | 9000X1350X1700 | 9450X1900X2400 | 9 |

| 9 | HDX-22.5 | 9000X1350X1850 | 9450X1900X2550 | 9 |

| 10 | HDX-25 | 9000X1450X1920 | 9500X2000X2800 | 9 |

| 11 | HDX-29 | 9100X1450X2000 | 9550X2000X3000 | 9 |

| 12 | HDX-30 | 11000X1350X2050 | 11250X2000X2800 | 11 |

| 13 | HDX-35 | 11000X1500X2200 | 11500X3100X4100 | 12 |

| 14 | HDX-40 | 12500X1500X2200 | 13000X3100X4100 | 12 |

| 15 | HDX-45 | 13800X1500X2200 | 14100X3100X4100 | 13 |